- Home

- Production Process

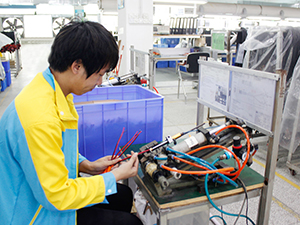

Production Process

Through this virtual tour, you will have a general knowledge of our manufacturing machinery and processing conditions.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Bending tester

We introduce this testing device to decide the bending capacity of cables and guarantee them reaching different customer’s demands. -

Salt spray testing instrument

Salt spray test leads to good rust resistance of metal components. -

Tension tester

The tester is applied to determine the tension of crimp terminals and cables. -

Insertion and extraction force testing equipment

According to the test results, technicians can evaluate the service life and make improvement.